Design for Manufacture

MRT’s technical team work in partnership with your designers to develop and adapt your product concept or design to optimise it for manufacture. We use our experience, expert knowledge, and the latest Solidworks CAD modelling software to help us achieve innovative designs which can be manufactured efficiently, consistently and economically.

READ More

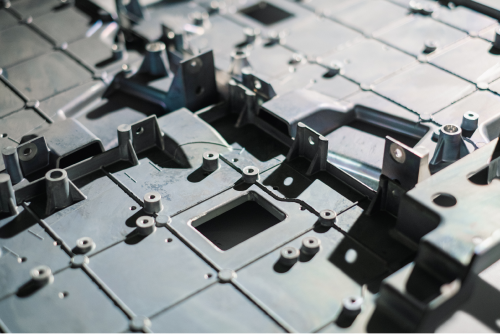

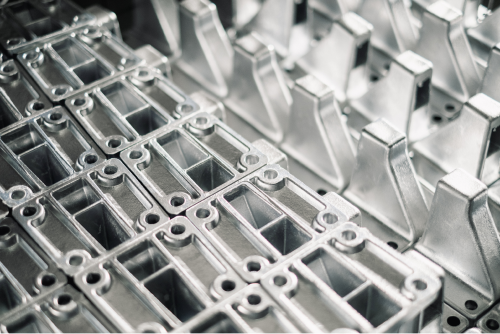

Tooling

Once component designs are approved, MRT will design and manufacture high quality production tooling. Using our in-house toolroom, and specialist partners in the UK and Europe, our dies, clip tools, jigs and fixtures are built to the highest specifications, for accurate and repeatable production and excellent tool life. All tooling is 100% owned by the customer.

READ More

Sand Casting

If you only require small production batches, sand casting offers a very economic introduction to casting, with low tooling costs and short lead times. This also makes it an ideal process for prototypes or pre-production trials. MRT provide sand castings in aluminium, zinc and copper based alloys.

READ More

Pressure Die Casting

MRT have one of the most modern aluminium high pressure diecasting foundries in the UK. Our production cells are all fully automated and feature real-time shot control and the latest peripheral equipment to ensure excellent quality and efficiency. MRT have a unique approach to pressure diecasting which makes it accessible even for relatively low volume demands.

READ More

Gravity Die Casting

MRT have a comprehensive in-house zinc and aluminium gravity die casting foundry, which employs highly productive micro-processor controlled hydraulic casting cells. MRT cast in a wide range of aluminium and zinc alloys, and have and in-house spectrometry to ensure excellent material quality.

READ More

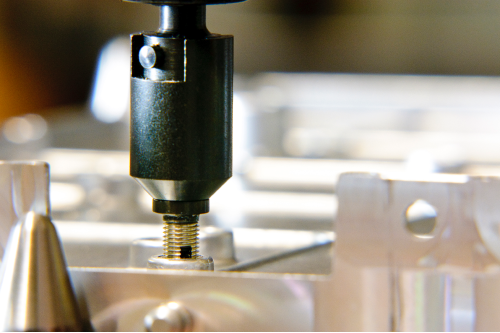

CNC Machining

MRT’s large in-house CNC machining facility features the fastest and most accurate milling and turning resources available. Innovative programming and fixture design enables MRT to achieve excellent dimensional accuracy, supported by our comprehensive CMM inspection facilities.

READ More

Surface Finishing

In-house linishing and vibratory finishing, plus our management of a long established team of local specialist partners for powder coating, painting, plating, anodising and other surface treatments ensure that MRT deliver fully finished components, meeting even the most demanding of cosmetic and environmental specifications.

READ More

Electro-Mechanical Assembly

MRT have a dedicated in-house electro-mechanical assembly facility where we build finished products utilising our castings and machined components along with specialist components sourced by MRT through our comprehensive supply chain. This enables you to outsource the entire manufacturing process to MRT if required.

READ More

Logistics

MRT ship our products worldwide. From our well connected warehouse in Andover we offer established customers a full service of stock-holding, kanban supply, specialist packaging, and even delivery direct to end-users. Utilise advanced and flexible ERP management software, we can offer individually tailored solutions to your exact requirements.

READ More